Co-engineering and TRL

From idea to customized machining solution

Manufacturers in the aeronautics, defense, space and nuclear sectors are faced with ever-increasing demands for innovation and performance. But the road to reliable industrial production is often a complex one:

- How do you transform an innovation into an operational machining process?

- How can you be sure that the technical solutions you are considering are viable for your specific materials and parts?

- How can you limit risks right from the design stage of a new CNC machine or robotic cell?

CRENO is at your side from the earliest stages, when your project is still at the stage of an idea or technical need. We support you as you move up the TRL (Technology Readiness Level), from from levels 2 to 5to transform your ambitions into concrete, industrializable machining solutions.

Machining co-engineering for your success

Our teams of specialized engineers bring you their technical expertise to :

- analyze your specific needs and part constraints (materials, dimensions, tolerances)

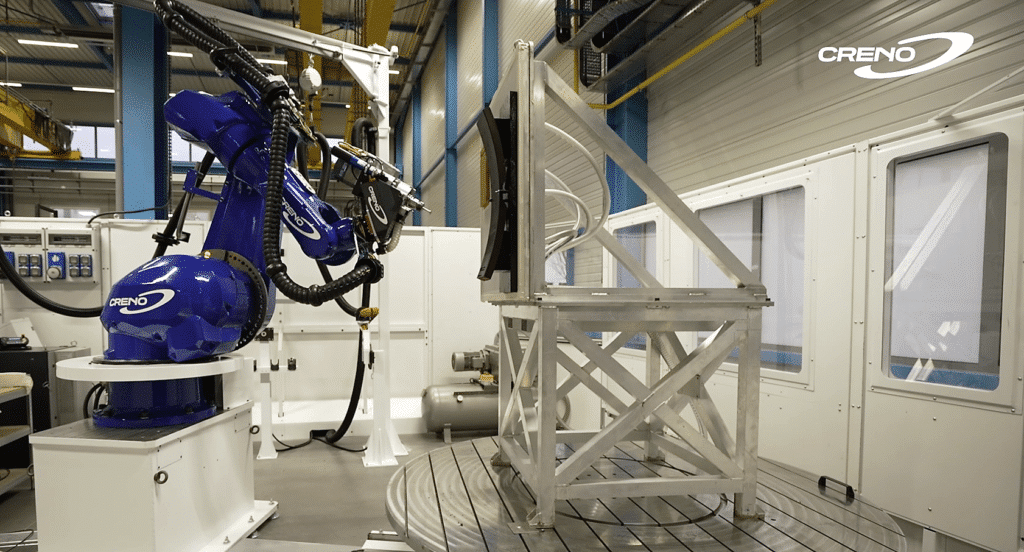

- design customized machining solutions, integrating multi-axis CNC, robotization or mobile machines

- evaluate machining forces, cutting tools and kinematics for your application

- propose proofs of concept (POC) and produce your first machining prototypes.

Thanks to this collaborative approach, you can quickly validate technical feasibility and secure your industrial choices at low TRLs.

Unique tools and technical resources for your studies and prototypes

CRENO provides a complete technical environment to support your TRL development:

- Integrated design offices Mechanical, electrical, automation, CNC programming.

- Simulation and digital twins Virtual validation before real testing.

- Rapid prototyping Rapid prototyping: production of the first machined parts on our own equipment.

- Tests on real materials Analysis of tool/material interactions and optimization of machining parameters.

Application Center industrial testing, proof of concept and process qualification.

the benefits of CRENO support :

Controlled risks

- Industrial risk reduction: you validate feasibility and technical choices before final investment.

- Time savings on time-to-market: the integrated design + prototyping approach accelerates your rise to industrial maturity.

Tailor-made performance

- Customized solutions: your CNC machine, robotic cell or mobile equipment is designed to perfectly match your industrial needs.

- Secure performance: your machining processes are tested on your specific materials before being transferred to production.

Why choose CRENO for your co-engineering and TRL ramp-up phases?

- 45 years of expertise in custom machining solutions for the aerospace, defense and nuclear industries.

- Recognized expertise in low TRL support, including prototyping and proof of concept.

- Unique resources in Europe, combining engineering, simulation, prototyping and testing on real parts.

- A single point of contact from design to industrialization, for complete project management.

Projects and achievements

CRENO is a partner of many manufacturers who have placed their trust in us right from the early stages of project development:

- design and prototyping of customized machining solutions for aircraft engine parts

- validation of acoustic multi-drilling processes for aeronautical nacelles

- development of robotized machining processes for composite aerospace structures

- design of mobile machines for on-site machining of sensitive nuclear components.

These collaborations enable us to optimize every step of the TRL process, right through to production integration.

Contact our experts

Does your project require technical support right from the start?

Would you like to validate your machining processes before investing in an industrial solution?

Our engineers accompany you from the idea to the realization of your custom CNC machine.