Custom CNC machining centers for defense and naval applications

Machining the impossible for your critical and large parts

The defense and naval industries face major challenges when it comes to producing structural and functional parts:

- machine solid or complex metal components with rigorous precision;

- guarantee impeccable quality on equipment designed for extreme environments;

- work on parts several metres long, which are often impossible to move.

CRENO has been supporting these strategic sectors for over 45 years, designing tailor-made machining solutions: multi-axis CNC machines, robotized cells and mobile equipment. These production resources are adapted to the specific requirements of your non-standard parts.

Mobile machines: mobile machining for large structures

Some components, such as hull parts for submarines, surface vessels or radar structures, cannot be moved without risk or prolonged immobilization.

CRENO designs mobile CNC machines capable of moving around the part, in the workshop or on site, to work directly on large structures.

This approach eliminates the logistical constraints of transportation and guarantees high-precision machining, even on complex surfaces.

Key benefits :

- time-saving: the machine comes to the part, reducing lead times and avoiding heavy handling

- enhanced safety: reduced risk of moving critical components

- machining accuracy of less than a tenth, even on parts several meters long, thanks to the dual encoder system and integrated probing.

Tailor-made solutions for defense and naval applications

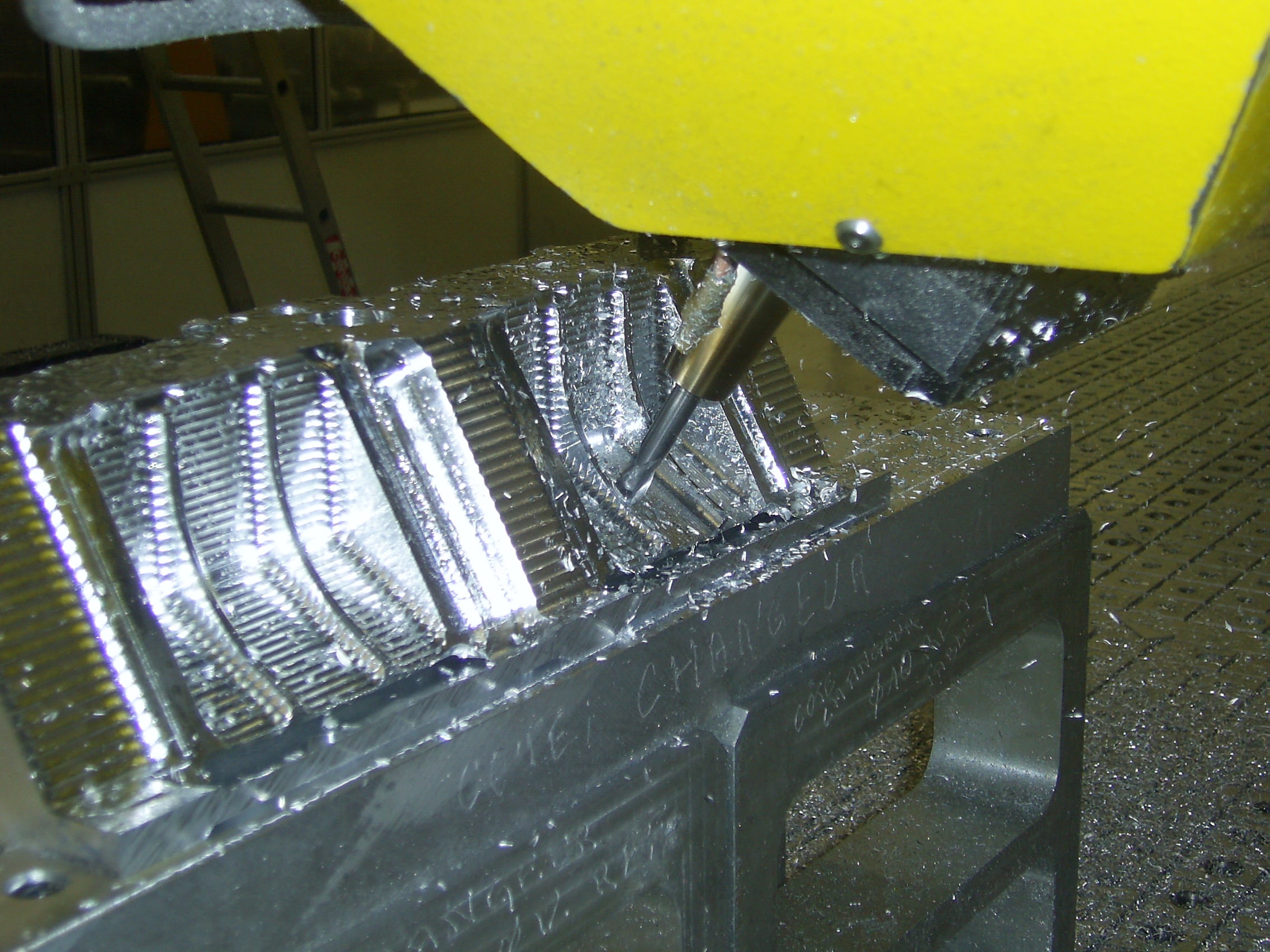

5-axis CNC milling for complex metal parts

Whether you need to machine armored chassis, naval structures or armament components, our custom multi-axis machines guarantee :

- machining oftechnical alloys such assteel, titanium and inconel;

- strokes of up to 20 metres, with consistent accuracy of less than a tenth over large dimensions;

- on-site or workshop integration, in mobile or fixed gantry versions.

Multi-process CNC robot cells

For a wide range of machining operations on small and medium-sized parts, our robotic cells offer you :

- flexibility to combine drilling, milling and routing on the same system;

- aSiemens ONE numerical controller for standardized programming and optimum repeatability;

- easy adaptation to your industrial spaces, even in constrained environments.

Why defense and naval manufacturers choose CRENO

- Recognized expertise on sensitive projects, in partnership with the sector’s major contractors.

- Solutions for large dimensions and technical materials.

- Mobile machines capable of working on site or in the workshop.

- Comprehensive support, from proof of concept to industrialization.

- Equipment designed to last over 30 years, with maintenance and retrofit solutions.

Reference projects

Our customized machining solutions have been deployed on critical applications:

- on-site machining ofsubmarine structural components

- manufacture of components for naval defense systems

- intervention on large-scale radar equipment.

Details of these projects remain confidential, in compliance with the security and discretion requirements specific to these sectors.

Process

Our solutions for the defense, energy and nuclear industries