Industrial deployment - Integrating your customized machining solutions

Fast, secure production start-up

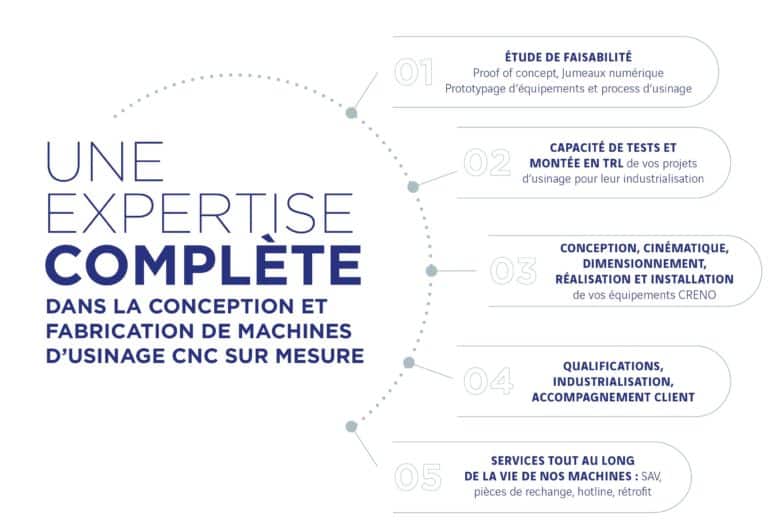

Designing a custom CNC machine or robotic cell is an essential step. But to get the most out of it, you need to ensure that it integrates smoothly into your workshops and ramps up without a hitch.

For over 45 years, CRENO has supported its industrial customers right through to on-site deployment.

Our goal:

- Install your equipment in production environments.

- Ensure commissioning and final adjustments on your first parts.

- Train your teams to get up to speed quickly.

- Enable you to reach your productivity targets quickly.

A turnkey solution: from installation to ramp-up

Our technical teams take care of all the operations involved in integrating your CRENO machine:

- On-site preparation Site preparation: study of access, adaptation of foundations, anticipation of production flows.

- Installation and commissioning Assembly, connections, CNC parameterization and safety checks.

- Tests on first parts : adjusting trajectories, validating tolerances, optimizing cycles.

- Ramp-up Support for your teams until production has stabilized.

Operator and maintenance training Training: appropriation of equipment, mastery of CNC control and management tools.

Ils nous font confiance

Adaptability: tailor-made solutions for your workshops

Every industry has its own specificities. CRENO designs equipment that adapts to your production constraints:

- Large multi-axis CNC machines gantries, moving tables, special kinematics.

- CNC robot cells CNC robotic cells: flexible, multi-process, can be integrated into your existing lines.

- Mobile CNC machines machines: for on-site intervention, without having to move your non-standard parts.

These customized solutions are designed to reduce footprintfacilitate access to machining areas and guarantee operator safety.

Benefits of industrial deployment supported by CRENO

- Reduced installation times Faster production start-up thanks to a dedicated team experienced in complex industrial environments.

- Reliable first production runs Your processes are optimized for your parts right from the start.

- Skills enhancement Your operators become autonomous on CNC and robotized equipment.

Controlled production Your CRENO machine integrates seamlessly into your industrial workflow.

Why choose CRENO to integrate your machining solutions?

- A single point of contact A single point of contact: from design to installation, for total project consistency.

- Multi-sector expertise aeronautics, defense, space, nuclear, energy…

- Tailor-made machines for your environment.

- An experienced field team CNC, robotics and industrial integration specialists.

Production-ready solutions From the moment the first parts are validated, your production ramps up.

Projects and achievements

CRENO has assisted numerous manufacturers with the installation and production of customized machining solutions:

- Integration of a multi-axis CNC machine for machining large aeronautical structures.

- Deployment of a multi-process robotized cell in a composite aerospace production line.

- On-site commissioning of a mobile machine for machining nuclear reactors.

- Support for an industrial sheet metal plant to automate aluminum routing.