Custom machining solutions for the energy and nuclear sectors

Precision control for critical parts in highly demanding sectors

The Pacte law and recent developments in nuclear safety have reinforced the need for manufacturers to guarantee the robustness and traceability of their equipment. In this context, CRENO supports major players in the energy and nuclear sectors by designing multi-axis CNC machines, robotized cells and mobile equipment adapted to large metal parts and sensitive environments.

Manufacturers in the energy and nuclear sectors operate in an environment where safety and regulatory compliance are non-negotiable. The manufacture and maintenance of large components, often subject to extreme temperature, pressure and radiation conditions, require customized machining solutions that are precise and reliable over the long term.

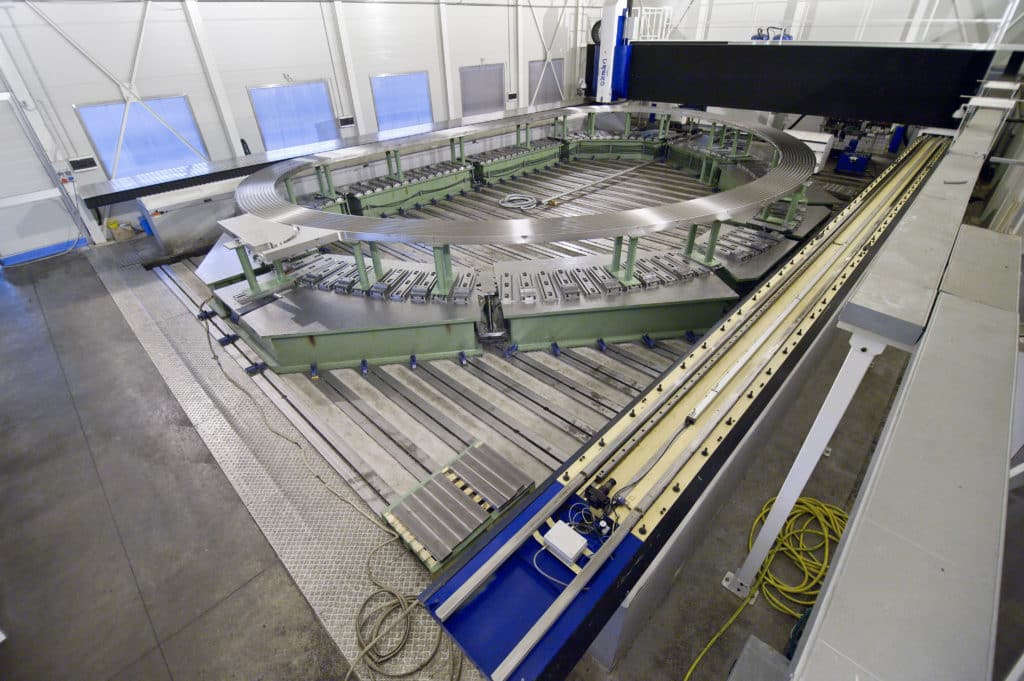

Mobile machines: on-site intervention to limit downtime and control risks

Parts of energy or nuclear facilities, such as containment vessels, reactor structures or pressure vessels, are often too large or too sensitive to be moved.

CRENO designs mobile CNC machines capable of operating directly on site, in installations, to carry out machining operations on very large structures, while guaranteeing sub-tenths precision.

This solution reduces handling operations, minimizes downtime and ensures that tolerances are maintained even on parts subjected to extreme conditions.

Key benefits :

- Reduced downtime: the machine moves around the part, minimizing plant downtime.

- On-site safety: limiting handling of critical equipment in sensitive or irradiating environments.

- Consistent precision: machining of large parts with sub-tenths accuracy, thanks to dual encoders and on-board control devices.

Tailor-made solutions for the energy and nuclear sectors

5-axis CNC milling for large components

Whethermachining tanks, flanges, mechanical assemblies or containment structures, our custom multi-axis machines guarantee :

- Machining of massive parts in steel, stainless steel or high-performancealloys.

- Strokes up to 20 meters, with sub-tenths accuracy, even on site.

- Long-term reliability to meet the robustness and durability requirements imposed by nuclear regulations.

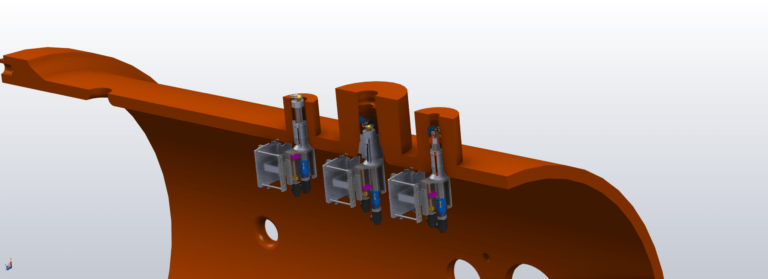

Multi-process CNC robot cells

For on-site adjustments or the manufacture of specific sub-assemblies, our robotic cells offer :

- The ability to combine drilling, milling and routing on a single system.

- ISO-standard programming on Siemens ONE numerical controls.

- Flexible integration, even in confined spaces.

Why choose CRENO?

✔️ Recognized experience on sensitive energy and nuclear projects .

✔️ Mastery of constrained environments and nuclear safety.

✔️Mobile machines capable of intervening on site for large parts.

✔️ A team of expert engineers, involved from proof of concept to industrialization (TRL).

✔️ Equipment designed to last over 30 years, in line with the requirements of the Pacte law.

✔️ An application center to validate your processes before industrialization.

Projects and applications

CRENO solutions are regularly called upon for critical interventions, including :

- On-site machining of nuclear reactor components, using a mobile CNC machine.

- Fabrication and rework of containment vessels and pressure vessels.

- Machining of steel structures for power plants and industrial infrastructures.

These operations are carried out in compliance with nuclear safety standards and enhanced security protocols specific to sensitive energy facilities .

Contact us for your industrial projects

Your equipment requires machining solutions adapted to the constraints of the energy and nuclear industries.

CRENO will work with you to design custom CNC machines and mobile solutions to meet these requirements.

Contact our teams to discuss your needs.

Process

Our solutions for the energy and nuclear industries