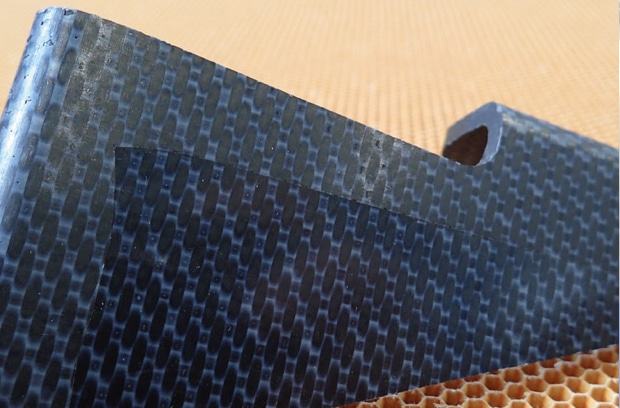

Usinage composite, métaux et bois

CRENO is known worldwide to have delivered numerous large-sized, customized gantry CNC 3 / 5 axis milling machines dedicated to composite milling. Since 2015, we have extended our range for milling composite parts and materials with robotic machining and robot cell solutions.

Designed for

Recognized expertise

- High Accuracy

- Strong Reliability

- More Efficiency

- Robust Design

- Environment Protection

Materials

- Diameters ranging from 0.55 to 2mm (0.021 to 0.08 inch)

- High precision and less delamination

- Individually controlled drill-hole depth

- No need to add additional finition

- Stability of the process

- Expertise in cutting tools

5-Axis Machine

High accuracy and strong reliability, heavy duty, customized, advanced machining solutions.

- A full range of multi-axis machines (Satellite panel machining, Overhead moving gantry, Shuttles)

- X axis travel up to 20m (66 ft)

- Y axis up to 9m (30 ft)

- Z axis up to 2.5m (8.2 ft)

- Spindle power up to 42kW

A full range of high-tech equipment: Countersinking, Orbital drilling, Compliance milling, Machining aggregates, Probes, Laser tool management…

Robot Cell

Lire

A full range of robotic machining cell solutions

- Multi-placement robot cell for more productivity

- Pendular robot cell for more flexibility

These solutions can be used in all industries likely to use robotic machining of composite materials.

Advantages of machining composite material on robots:

- High productivity, in particular due to the pooling of tools and multiple installation options

- Loading and unloading during machining operations

- Better access to machining areas